Asian Textile Studies

Contents

Mud Dyeing

Sumba

Savu

Sarawak

Kalimantan

Sumatra

Sulawesi

Java

Bali and Lombok

Flores

West Timor

Timor-Leste

India

Burma

Thailand

Vietnam

The Philppines

Japan

The Biochemistry of Stagnant Ponds

The Chemistry of Dyeing with Iron and Tannins

Bibliography

Mud Dyeing

An important way of producing a relatively fast range of grey and black was to treat a textile with tannin-rich plant material and then immerse it in mud from a stagnant pond, river or paddy field. It is important to note that although the technique is referred to as mud-dyeing, the mud is not the actual dye but is simply a mordant - it is the tannin that is the dye. The initial tannin-dyeing stage is a hot process, but the subsequent mordanting in mud is cold.

Alfred Bühler thought that mud-dyeing was the most primitive and earliest form of mordant-dyeing (Bühler 1948, 2496). His views were echoed by Robyn Maxwell, who suggested that ‘black mud dyeing’ was one of the oldest colouring techniques in Southeast Asia (Maxwell 1990, 96). It is certainly easy to see how the technique may have been discovered following the accidental dropping of a partially dyed article in river mud.

Yet while this idea seems intuitively correct, there is only circumstantial evidence to support it, mainly from the close association of mud-dyeing with the production of barkcloth. Barkcloth fragments and beaters have been recovered from Neolithic archaeological sites in southwest China, Taiwan, the Philippines, Thailand, Cambodia, Vietnam, Malaysia, Borneo and Sulawesi, some dating back 5,000 to 6,000 years (Cameron 2006, 65-74).

Mud-dyed barkcloth has been, or still is, a tradition among the more isolated communities of the region, some of whom are the descendants of the earliest immigrants:

- the Penan of Sarawak (Ball 2009, 119-120)

- the Negritos of the Philippines (Fox 1953, 258; Pastor-Roces 1991, 25 and 84)

- the Kulawi of Western Toraja (Raven 1932, 377)

- the Maisins of Papua New Guinea (Hermkens 2013, 81), and even

- the Maori of New Zealand (Daniels 1996).

It is also noteworthy that the two most significant mud-dyeing regions in Indonesia, Central Sulawesi and Sumba, have an extensive and recent tradition of making barkcloth.

Elsewhere we know that the production of black-mud silk using gambier in the Guangdong Province of China dates back to the Ming Dynasty, 1368 to 1644 AD (Bruno 2014). Mud dyeing in the Ryūkyū Archipelago of southern Japan dates back to the seventeenth century.

Mud-dyeing has been reported for many places across mainland and insular Southeast Asia, but has rarely been documented in any detail (Hamilton 1989, 50). Today it is practised in just a few locations.

Return to Top

Sumba

In the past the majority of the inhabitants of Sumba Island dressed in dark grey or charcoal black homewoven cotton or barkcloth. Colourful warp ikat was at that time only produced within the narrow habitable eastern coastal strip of East Sumba, where it was strictly confined to the nobility and only worn for ceremonial occasions. The black colour of the majority of Sumbanese clothing was achieved by means of mud-dyeing.

A young man dressed as a noble flanked by a slave and a commoner wearing dark cotton clothing, most probably mud dyed. Prailiu, East Sumba, 1931

(Image courtesy of L. C. Heyting Collection, Leiden University Library)

There are many early historical reports that describe the widespread habit of wearing dirty black clothing. One of the earliest reports was from the trade commissioner J. D. Kruseman, who found that on the coast of Lamboya, West Sumba, men wore a fringed long black cloth for ‘solemn’ occasions (Kruseman 1836, 63). According to the Dutch Resident at Kupang Diderik Johan van den Dungen Gronovius, who spent seven months on the island in 1846, the dress of the average Sumbanese man was simple but filthy. They wore a black cloth and a kind of black bellyband held in place with strands of rope. These were worn year after year and were never washed. The women only wore a long, black, very narrow sarong of native fabric, which was usually decorated on the bottom with small beads of seashells. After Sumba became an official Dutch colony in 1859, Kupang installed Samuel Roos on the island as its first Controleur. He served from 1866 to 1873 and towards the end of his term reported how men wore a heavy cotton blanket with fringed edges that was initially white but was dyed black after it became dirty. The man’s long rusu banggi torso wrapper, on the other hand, was woven from black-dyed cotton. Women wore a very thick, coarse and narrow cotton sarong, which was likewise dyed black (1872, 12-13). Later in 1890 the naturalist Ten Kate found that along the more remote south coast and into the highlands, men’s blankets were still being made from barkcloth (1894, 551-552).

In West Sumba, travellers and missionaries who visited the area prior to World War II reported that women in all districts other than Kodi wore only simple black sarongs (Hoskins 1993, 237). In the domain of Lamboya women wore both barkcloth and cotton sarongs. The latter were woven from local cotton and were therefore white, but were dyed black with mud after prolonged use (Keller 1993, 253). Following a death, the first funeral shroud used to wrap the corpse had to be blacked in a mud bath (Geirnaert 1993, 212; Keller 1993, 254).

Some indication that older lau in private and museum collections were originally mud-dyed can be gauged through their partial disintegration as a result of the astringent effect of acids produced during the iron-mordanting process (Holmgren and Spertus 1989, 38).

It is clear that mud-dyeing must have once been widespread across the island, although early historical accounts referring to it are exceedingly sparse. The American butterfly collector, William Doherty, recounted a visit to Kawangu in 1887. After leaving Waingapu he passed through Kabaniru before crossing the Kambera River, where women were dyeing cloth in the black mud (1891, 156).

A century later Monie Adams, an American cultural anthropologist, found that women in the northern East Sumba domain of Kapunduk were occupied during the early part of the rainy season with planting and mud dyeing (1971, 323). It was essential that women’s garments for everyday wear were dyed black using a ‘hot’ dye process. The garments were soaked in a hot dye bath produced by boiling a mixture of plants in water. Afterwards the dye was ‘set’ by immersion in one of the mud basins along the riverbank. Monie Adams found that the women actually sat in the mud basin to do this work and were extremely embarrassed to be seen doing so. The black-dyed cloths were regarded not as decoration but as common requirements for Kapunduk female identity - "just as the process of conception is common to all women". Even in 1984, the French ethnographer Danielle Geirnaert-Martin concluded that black mud-dyeing was still widespread throughout East Sumba, conducted by women in secret beyond the gaze of men (1992, 105). Mud dyeing marked the return of the rains and of agricultural fertility.

There was a strong mud-dyeing tradition in the most northerly part of East Sumba, the region of Wunga near Cape Sasar, where indigo-dyeing was prohibited (Geirnaert 1993, 212-213). Cape Sasar is considered to be the location of where the first ancestors arrived by sea and is therefore where the deceased return to their place of origin. Danielle Geirnaert suggests that indigo-dyeing may be taboo in this region because it is associated with reincarnation, whereas black mud-dyeing is acceptable because it symbolises the putrefying stage of death.

The situation today is radically different – mud-dyed textiles are generally only found as family heirlooms. Across the whole of Sumba Island there now remains just one active mud-dyer – Karanja Ngana, who was born in the small hamlet of Meurumba, adjacent to the royal ceremonial village of Uma Bara in the former domain of Pau, East Sumba. It is not far from the small coastal town of Melolo. The craft of mud-dyeing appears to have continued longer in this area than elsewhere.

Karanja Ngana is a short, wiry and immensely tough woman, without an ounce of fat on her body. She has no idea when she was born – she is probably in her fifties but looks around seventy, the consequence of a physically hard and demanding life. Her mother was a mud-dyer too but died before Karanja was twenty-years-old. Karanja was therefore taught to mud-dye by her stepmother, Lunga, who is still alive but no longer active. Karanja’s husband died six years ago leaving her with just one fifteen-year-old daughter who occasionally helps her with the dyeing, as does her young nephew, Ten. Mud-dyeing is not gender specific – in the past it could be conducted by either women or men. Having been brought up close to the royal kampong of Watu Hanangu just outside Uma Bara, Karanja used to undertake commissions from the royal family of Pau, dyeing their lau pahikung. Today she only dyes skeins of two-ply commercial cotton, which she sells at the early morning Thursday or Friday market at Mengetinggi, just outside of Melolo.

Our first few attempts to visit Karanja were unsuccessful. On our first two visits it was raining and too dangerous to climb down the steep slippery path to her simple thatched house built in an isolated spot at the bottom of the valley close to the Panyuambang River, which cuts through the high plateau some 15km from the coast. We eventually managed to visit her at her house in April 2017 and again in August 2019. In the past there were many mud-dyers operating in this vicinity. People attempted to mud-dye in many different regions but the process only worked in certain restricted areas that had the right kind of mud.

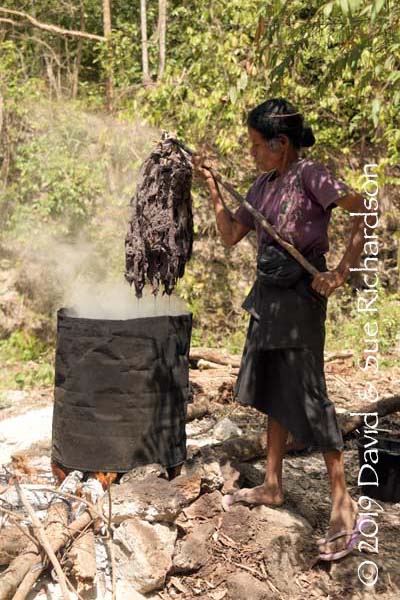

Karanja heads off bare-footed into the forest, balancing her skeins of cotton and our lunch of corn on the cob on her head

Karanja was keen to start work on her dyeing and sprinted off ahead of us upstream to show us the way to her dyeing site, with a sack of cotton yarn and two-dozen cobs of corn balanced on her head. She dyes her yarns about a kilometre upstream in a small forest clearing next to the fast-flowing river, where there is an old steel oil drum perched on stones next to three small rectangular pits cut into the ground that are partially filled with water. Prior to our arrival she had made offerings to her ancestors in order for them to sanction our visit to her sacred clearing.

A location next to the river is vital, since the process demands a significant supply of fresh water for rinsing the yarns. However this particular area is alive with the spirits of the forest. An old banyan tree had previously overlooked the site, but Karanja was concerned that the tree had become infested with evil spirits who were intent on preventing her using this location for dyeing. She responded by building a fire around its trunk and burning the tree down.

Obviously the mud-dyeing process requires a source of mud from a stagnant pond, not a fast-flowing river, but such ponds are located up on the limestone plateau above the valley where they provide drinking water for grazing cattle. The black mud has to be scooped up from the middle of one of these ponds and then carried down to the riverside in buckets. Karanja either carries down ten kilogrammes of mud herself or gets help from Ten, her young nephew. The mud does not have to be used immediately – it will remain active for many years. It can therefore be collected and dried and then used later just by adding water. Karanja still has some mud that she collected in 2016. However if it is to be used for dyeing soon, the mud should ideally be left in the water pits for three weeks prior to use.

Ten scoops up mud from the middle of a stagnant pond in the pouring rain

Once Karanja arrives at the clearing she fills the oil drum with river water and lights a fire below it using dried tree branches and cornhusks for tinder. The first task is to prepare the tannin dye bath. This requires bundles of leaves and branches from two tannin-rich trees:

- lobung (Syzygium lineatum or the very similar Decaspermum humile) - two evergreen sub-canopy trees that grow up to 30 metres tall and

- haying (Woodfordia fruticosa) a large shrub growing up to 5 metres tall with long, spreading branches and small red flowers.

Sprigs of shiny green lobung

Sprigs of soft green haying

Karanja’s nephew Ten tying bundles of haying

Two bundles of haying are required for every single bundle of lobung and each bundle can be used to make two dye baths. The bundles are added once the water is close to boiling and are left to infuse into the boiling water for about ten minutes before they are removed using a long stick. Each bundle can be used twice before it is exhausted. Meanwhile the mud pits are stirred by hand to disperse the ferrous iron into the water.

The fire is lit under the drum of water filled with the bundles of branches

After the bundles of lobung and haying are removed, the hanks of commercial yarn are lowered into the tannin dye bath

The dyed yarns are removed from the tannin dye bath and are immediately immersed in the mud pit and are thoroughly kneaded in the mud and water mixture

The yarns are repeatedly immersed in the mud before being wrung out

The mordanted yarns are thoroughly rinsed in the fast-flowing stream

Now the skeins of commercial cotton yarn can be added to the hot tannin dye bath, and must be stirred so that every part is completely wetted. After ten minutes the skeins have turned grey and are removed and put on the ground next to the mud pits. The hot hanks are then immersed into the mud and rotated so that every part comes into contact with the mud paste. The grey immediately becomes darker. The hanks are then gathered into bundles of five and are wrung out over the mud pit. The wrung hanks are taken to the river and are given a thorough wash in the flowing water before being wrung out again. This rinsing lightens the yarns as the free tannins are removed. Back at the drum the skeins are immersed in the tannin bath for a second time and the whole process is repeated. As the work progresses, corncobs are placed in the fire below the oil drum so they can cook for our lunch.

Depending on the strength of the mud it requires three immersions to get a dark grey and six or seven to get a near black. There is sufficient mud in one pit to mordant around ten bags of commercial yarn.

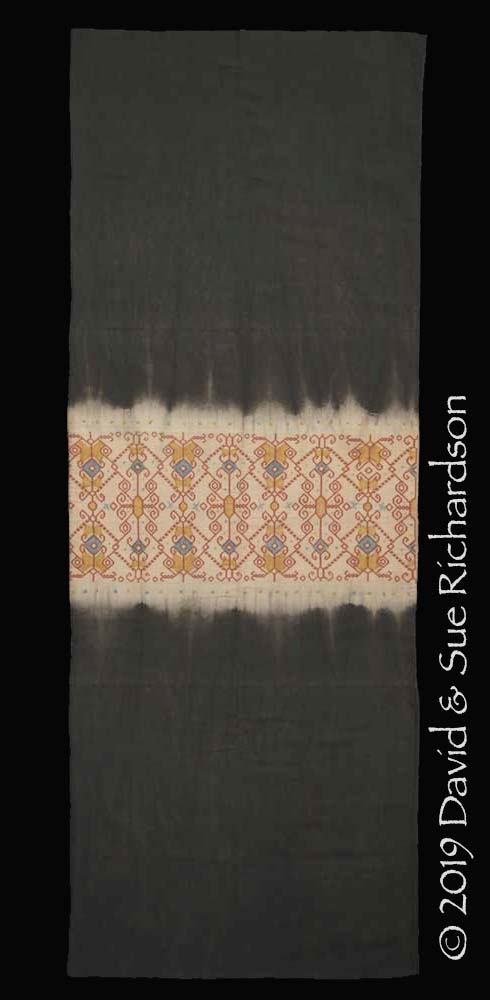

Although Karanja currently concentrates on producing mud-dyed yarn, in the past she also used the same process to dye ikatted yarns that could then be woven into a woman’s skirt (lau) or a man’s blanket (hinggi). Some of the most demanding work came from Tamu Rambu Pakki from nearby Uma Bara, the granddaughter of Tamu Umbu Hiya Hama Taki II, who was the Raja of Pau from 1893 until 1932. This royal princess would commission Karanja to mud-dye some of her ceremonial sarongs that she had decorated with supplementary warp. These are known as lau pahikung pakapihak (literally sarong decorated with supplementary warp or pahikung that is mud-dyed). It was the responsibility of the weaver to tightly bind the central decorative section of the sarong with the outer floral sheath of an Areca palm, called a kuamba, so that it would completely resist the dye, and to then mud-dye the entire item until it was a near black. The result was that the ends of the sarong appeared to have been zone-dyed. This was clearly a risky process – if any of the dye penetrated the central section, the sarong would be ruined.

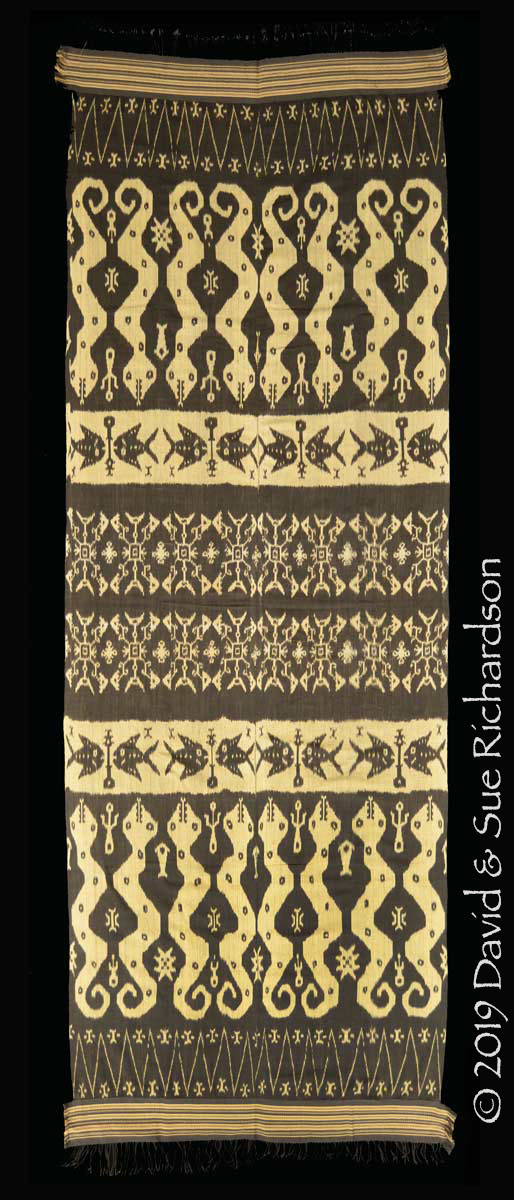

A lau pahikung pakapihak, sometimes called a lau pahikung pa ka kuamba, woven by Tamu Rambu Pakki in 1985 and dyed by Karanja Ngana. Richardson Collection.

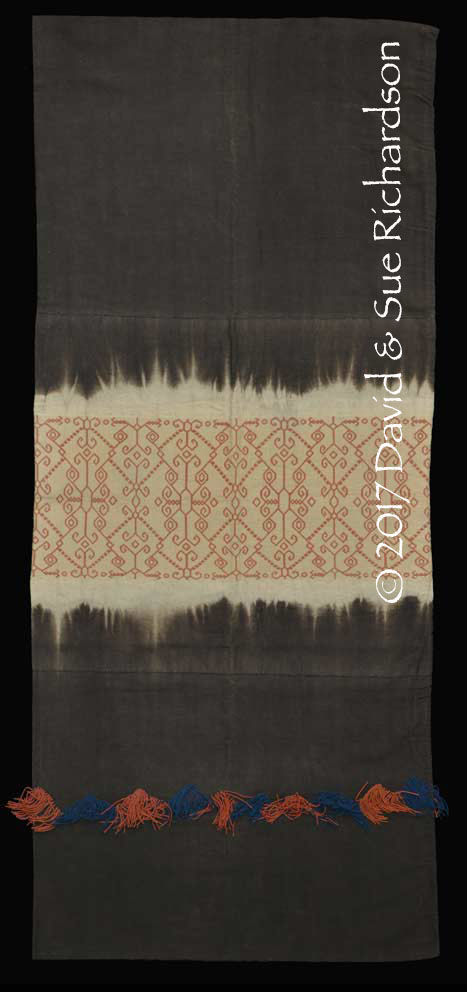

On Sumba, mud-dyed skirts are often called lau pakapihak. The word piha means to fall or wilt and is modified by ka.-.k into kapihak, meaning mud. The prefix pa turns the noun into a verb, so the process of mud-dyeing is called pakapihak – literally to mud or muddy. Others refer to them as lau lumpur, lumpur being the Indonesian word for mud.

A lau pahikung nggeri pakapihak, also known as a lau pa ka kuamba, woven by Tamu Rambu Hara Adji, the third daughter of Tamu Umbu Hiya Hama Taki II, the Raja of Pau from 1893 until 1932. The skirt was woven before being zone mud-dyed. Richardson Collection.

A three-panel zone mud-dyed ceremonial lau pahikung nggeri pakapihak, also known as a lau pa ka kuamba, woven a century ago by the grandmother of Tamu Rambu Pakki at Pau. Richardson Collection

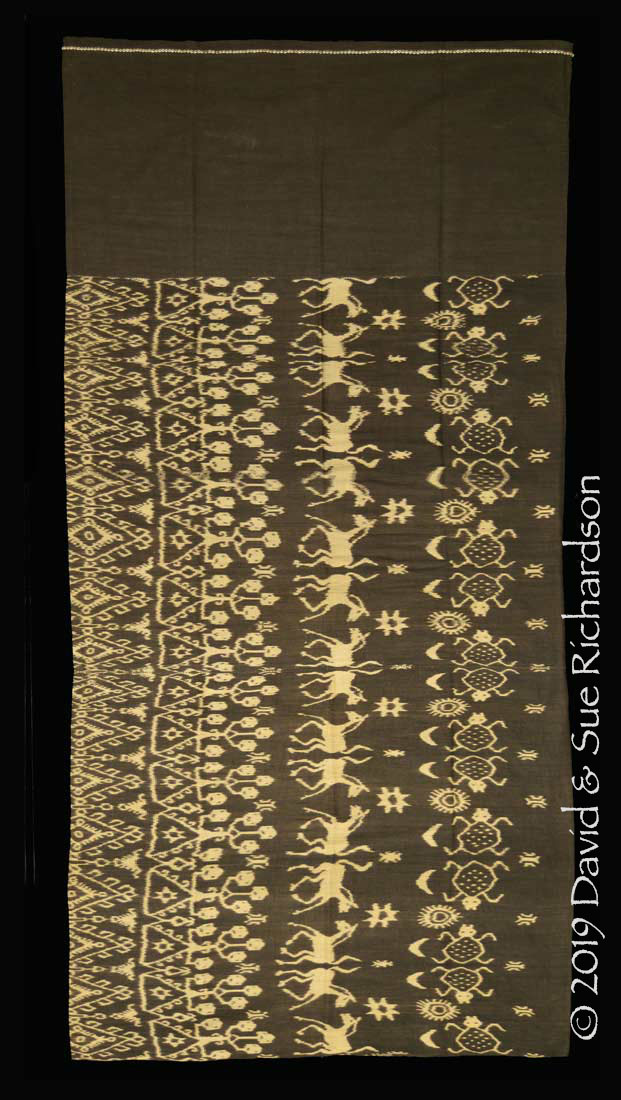

In 1977, Karanja dyed the ikatted yarns for a huge woman’s tube skirt known as a lau payubuh that was intended to be worn by a woman for her funeral as the outermost of all her dresses. The term payubuh means to cover your body (with a blanket or sarong) when you sleep. One of her relatives who lived close to Rindi created the design and bound the ikat.

The woman's lau payubuh funeral shroud dyed by Karanja Ngana in 1977

Richardson Collection

Some years later she dyed the ikatted yarns for an extremely rare hinggi hiamba pakapihak man's blanket.

An extremely rare hinggi hiamba pakapihak, mud-dyed by Karanja Ngana in 1990.

Richardson Collection

As we have seen, the process of mud-dyeing is long, labour-intensive and repetitive. On Sumba, Karanja Ngana buys skeins of white cotton and after mud-dyeing them sells them for a modest mark-up. It is not surprising that few women would choose to take up this lonely, arduous and unprofitable profession.

Karanja Ngana, one of the hardest working women on Sumba

The two tree species used by Karanja Ngana produce a tannin bath that is grey and the effect of the mud mordant is simply to darken and fix its shade. However only a minority of tree species, such as logwood, produce a grey or black dye. On Sumba it is often claimed that textiles that are dyed a plain tone of brown have also been mud-dyed. We have previously been sceptical of this claim for two good reasons. Firstly the majority of tree and plant-based tannins produce excellent wash-fast brown dyes, making it unnecessary to mordant them with iron. Secondly iron tannates are always dark grey or black not brown, so a textile that has been naturally dyed a pure brown cannot have been mud-dyed.

The answer to this conundrum was provided when we met dyers from Amami Oshima Island, Japan, where they also mordant some textiles with mud after they have been dyed with brown tannins. The effect is to transform some of the brown tannins into grey iron tannates – after it has been treated with ferrous mud the brown cloth takes on a grey tone. The implication is that if a naturally dyed brown textile does not have a grey tone, it has not been mud-dyed but has simply been dyed with tannins.

Lower panel of a lau pahikung nggeri, woven using mud dyed yarns in Ngeangandi in the domain of Pau over 40 years ago. Richardson Collection

Return to Top

Savu Island

Surprisingly there is no memory of mud-dyeing ever having taken place on Savu Island (Duggan 2016, personal communication).

Return to Top

Sarawak

Many of the tribes on Borneo produced decorative baskets by dyeing some of their rattan strips jet black. They did this by first colouring them using the leaves and stems of indigo or tarum and then soaking them in river mud for ten days (Hose, McDougal and Haddon 1912, 213). The Iban called the river mud ladu and also used it to dye women’s bidang or ‘petticoats’ (Haddon and Start 1936, 20 and 150).

Marieanne Ball (2009, 119-120) has recorded mud-dyeing among the hunter-gatherer Penan people of northern Sarawak, who use it to colour their rattan, bamboo and other materials. They boil local leaves in water for two to three hours and either add river mud to the mix or apply the mud to the rattan after it has been steeped in the leaf solution, leaving it to dry overnight. The process is repeated to produce darker tones. The presence of either oil, fat or chlorine in the water interferes with the process.

The Malays of western Borneo dyed their silk black by soaking it in the leaves of Sapium indicum cooked in ferruginous water and then giving it a final treatment in clayey mud (Jasper cited in Bühler 1941, 2497; Brunello 1973, 22).

Return to Top

Kalimantan

Mud-dyeing has been reported among the Iban (Fraser-Lu 1988, 31). In the early 1900s the Dayak communities of the Kendawangan and Membuluh rivers in south-western Kalimantan used iron-rich mud to blacken their umbong taping skirts, which were made of reddish-brown fiscus barkcloth (Hamilton 2007, 60). The technique used was never recorded.

Return to Top

Sumatra

Marsden noted that on Sumatra black was sometimes achieved by stamping indigo-dyed cloth into iron-rich lake mud (Marsden 1811, 95).

Mud-dyeing was practised among some of the Batak peoples of northern Sumatra. The details are sketchy but in the Toba region an intense black was achieved by treating the yarns with a tannin infusion called sigira gira, made from the tree bark of joring (Archidendron bigeminum) and then burying them in gambo or rice-paddy mud (Jasper and Pirngadie 1912, 68). In the eastern Batak region, now known as Simalungun, black was obtained by first immersing the yarns in a sigira gira solution made from the leaves and bark of jambu (Syzygium spp.) and the leaves of antahosi (species unknown) and then submerging them in a bath of mud (tanah porsigiraan) (Jasper and Pirngadie 1912, 69).

On Nias Island they produced a black dye by boiling the leaves of two unknown local plants, lawaate and mburune, with mud and water. Yarns or cloth were immersed in the resulting thick liquid for two or three days (Jasper and Pirngadie 1912, 69).

The Minangkabau once converted indigo cloths imported from India to black by dyeing them in a bath of mangosteen fruit peel and the bark of ‘katapping‘ (myrobalan or Indian almond) before fixing them in mud (Marsden 1784, 79).

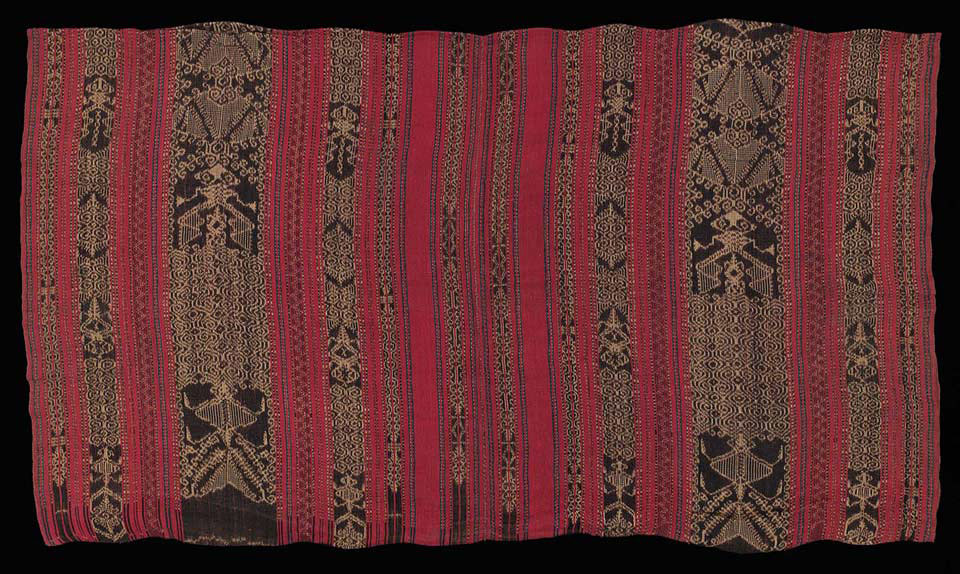

In Lampung one old recipe is based on a combination of sappan wood and ‘ketapan‘ (myrobalan) bark, the first soaked for three days, the second then added for one night (Totton 2009, 47). Finally mud was added to the dye bath to deepen the colour. According to Matiebelle Gittinger in 1972 (cited by Totton 2009, 47) the dyeing techniques used in West Lampung for the yarns used in tapis and ceremonial palepai ship cloths (and presumably tampan) were the same.

The black in this tatibin from Samangka Bay, Tanggamus Regency, Lampung, was probably made from tannin-rich tree barks and mud or clay (Image courtesy of Yale University Art Gallery)

In the lowland district of Telok Betong in Lampung they produced a tannin bath by boiling the barks of djali (?) and bungu (tropical crepe myrtle, Lagerstroemia floribunda) with the aluminium-rich leaves of njari (Symplocos spp.). After dyeing and drying, the yarns were mordanted in a bath of black clay and water (Jasper and Pirngadie 1912, 67).

Mud-dyeing has recently been recorded in both Aceh and at Martapura, halfway between Palembang and Lampung (Subagiyo 2007)

Return to Top

Sulawesi

Central Sulawesi was not only an important centre of mud-dyeing but also had a long tradition of producing barkcloth, known locally as fuya. The barkcloth was darkened by immersing it in a bath of cooked tree bark, treated with local plant materials such as chewed rhododendron, and then dragged through river mud (Howard 2006,139). Among the various non-Torajan ethnic groups of Central Sulawesi, mud-dyeing was practised by both the Kulawo or Kulawi and the highland Tobaku. The Kulawi of Koelawi district, Western Toraja, used mud to dye their fiscus barkcloth black (Howard 2006, 32). The Uma-speaking Tobaku, who had a preference for black barkcloth clothing, obtained a deep, permanent colour by immersing a complete garment in the blackest mud for five or six hours on a muddy riverbank or in a rice field (Aragon 1990, 41). It was then rinsed in the river before being given one final beating.

Unmarried girl from the Besoa Valley wearing a darkened, double-folded barkcloth skirt

(Image by Wolanda Hindia, Hendrik Kraemer Institute, Oegstgeest, Holland)

In the Tana Toraja Regency of Central Sulawesi, both the Sa’dan Toraja and the Mamasa Toraja produced sacred mud-dyed cotton textiles – among which the rectangular mawa’ or maa’ and the long narrow sarita are the most well-known (Nooy-Palm 1989, 163-180). Both were flown from tall bamboo poles before the house of a dead person, or wrapped around the head of the wooden effigy representing the deceased. Some of the earliest were imported from India via Java, but after 1880 many indigo-dyed versions were imported from the Van Vlissingen printworks at Hemund in Holland. At the same time, many were produced locally, being stamped with a resist paste using carved wooden blocks and hollow bamboo tubes (Nooy-Palm 1989, 172-173). The dyeing techniques were not fully recorded, but black appears to have been obtained by dyeing the stamped cloths in a bath of cooked leaves taken from the cultivated bilante tree (Homalanthus populneus) and then immersing them in mud.

Late 19th century Sa’dan Toraja sarita that appears to have been resist mud-dyed

(Image courtesy of the Indo-Pacific Art Collection, Yale University)

Following a death, the Sa’da Toraja blackened the clothing articles of the deceased, as well as the woven funeral garments (including the widow’s hood or pote) in the same way. The ma’bolong (‘blackening of the clothes’) ritual was the final concluding act of the official period of mourning. It was held on the afternoon of the day following the burial, and was accompanied by the sacrifice of a chicken. The women, all dressed in black, pounded the leaves of bilante in a stone mortar before boiling them in water (Nooy-Palm and Schefold 1986, 42-43). Meanwhile it was the responsibility of one of the men to collect some bluish-black muddy clay from a nearby sawah paddy field and empty it into a hole dug in the ground. The bundle of clothes were immersed in the mud, dried in the sun and then washed in the mud again. Finally the boiled brownish bilante infusion was poured into the mud hole containing the clothes, which were then dried and washed. The darkened clothes were always laid out on the ground on the west side of the house.

Washing funeral clothes in the sawah mud (From Nooy-Palm 1986)

Return to Top

Java

In Bandung and Karawang, just west of Jakarta, yarns were coloured black by first dipping them into a tannin bath made from the leaves of either kareumbi (the bleeding heart tree, Homalanthus populifolius) or malaka (emblic myrobalan, Phyllanthus emblica) and then immersing them into a mud bath (Jasper and Pirngadie 1912, 66).

In Pekalongan red morinda-dyed yarns, especially those that had been bound for ikatting, were coloured black using the leaves of the kisireum tree (black plum, Syzigium cumini) and black earth (Jasper and Pirngadie 1912, 65).

In Tasikmalya they used mud-dyeing to achieve a dark purple from red-dyed yarns, and black from indigo-dyed yarns (Jasper and Pirngadie 1912, 66).

In Sukanegara they produced black yarn by boiling tjitoear mixed with either indigo or black mud (Jasper and Pirngadie 1912, 66). Tjitoear or tjitoewar was a cocktail made from the leaves of the December tree (Erythrina hypaphorus) groundnut oil, galangal root, white onion, Capsicum peppers, and ash water made from burnt paddy-rice straw.

Mud-dyeing is still practised in the same centres of Pekalongan, Tasikmalya and Sukaneggra today (Subagiyo 2007)

Return to Top

Bali and Lombok

We have been unable to find any historical references to the use of mud-dyeing on Bali or Lombok. However mud-dyeing has been recorded there recently (Subagiyo 2007).

Return to Top

Flores

On Flores mud-dyeing seems to have been preserved mainly in the central regions of Ngada and Ende. Paul Arndt (1963, 150) described the mud-dyeing process used in the Ngada and Lio areas of Flores. Yarns were first boiled with various types of bark containing tannin, then submersed in the mud of a buffalo wallow to which algae and other plant matter had been added.

Among the Ngada people mud-dyeing was practised in the high mountain villages such as Mangulewa, the highest settlement on Flores, possibly because indigo did not grow at this altitude. The people of this village grew cotton on land they owned in nearby Soa and produced plain garments dyed with mud instead of indigo (Hamilton 1994, 104). The Ngada referred to the mud for making black as pisa (Molnar 1998, 45). In Soa itself, girls wore single-panel nai do’i sarongs woven from mud-dyed yarns and finished with coloured narrow edges (Hamilton 1994, 111).

In the Sara Sedu region of Ngada Regency, where weaving was only introduced into one village by the Dutch in the 1920s, the Hoga Sara produce plain mud-dyed textiles for making lawo pisa sarongs and men’s lué pisa blankets (Molnar 1998, 43).

Return to Top

West Timor

On Timor mud-dyeing is often combined with indigo-dyeing (Hamilton 2014, 46). Tannin is derived from at least four small tree species, the most common being the seaside laurel Phyllanthus reticulatus (Cunningham, Kadadi et al 2014, 96). The three others are the thorn bush (Harrisonia brownii), bleeding heart (Homalanthus novoguineensis), and Queensland poplar (Homalanthus populneus).

Leaves and berries of seaside laurel (Phyllanthus reticulatus)

Although the Amarasi in far western Timor no longer use mud-dyeing today, it seems that they did in the recent past. They soaked their threads overnight in a bath made by boiling mango bark and other local plant materials, and then buried them in lake mud for a whole day (Warming and Gaworski 1981, 72). Usif Robert Koroh, the current chief of the Amarasi, recently told us that mud dyeing in Baun, Kecamatan Amarasi Barat, was normally undertaken in October and November, after the leaves had fallen into the local lakes.

The tradition of mud-dyeing has been preserved in Bokong, Amanatun Utara. They produce a very colourfast black by boiling the mature leaves of Harrisonia brownii and leaving them to soak for two days. The leaves are removed and the tannin-rich solution is used to scrub the yarns, which are then immersed in the mud and, after a thorough scouring, are washed. To achieve a deep black this cycle must be repeated eight times (Cunningham, Kadadi et al 2014, 96).

The highly important weaving region of Malaka Regency (formerly south Belu), encompasses a number of well-known textile-producing centres such as Besikama, Fahiluka and Laran on the coastal plain and Manlea, Norubo and Uaba’uin in the interior uplands. In the past, weavers from both the lowlands (fehan) and the uplands (foho) produced plain black hand-woven cotton textiles using a combination of indigo and mud-dyeing (Hamilton and Taromi 2014, 141). These textiles were used widely for everyday and sometimes ceremonial wear, but were progressively superseded from the 1950s onwards by cheap imported machine-woven cloth supplied by Chinese merchants in Betun.

Return to Top

Timor-Leste

Mud-dyeing is ingrained among the Ema, known as the Kemak by their neighbours, who live in the mountainous Marobo region of Bobonaru District, close to the border with West Timor. Local weavers have a strong tradition of dyeing their hand-spun cotton textiles with indigo, followed by tannin and mud (Barrkman 2014, 172). It is thought that they have done so for centuries. Indeed the Tetun weavers in the villages of Suai Loro and Camenaça in neighbouring Cova Lima District regard Kemak textiles to be the ‘original’ tais. The black cloths of the Kemak also seem to be the inspiration behind the large black Suai-Camenaça funeral shroud known as a tais koli.

The anthropologist Brigitte Clamagirand documented the different Kemak dyeing processes in 1972 (Clamagirand 1972, 63-66). They were more recently studied by Joanna Barrkman and documented in a video by the Fowler Museum.

The cotton yarns are first dyed with indigo in the normal way, using from 10 to 30 immersions to achieve the required depth of colour. Only then are they mud-dyed, using two tannin-rich plant sources – the leaves of seaside laurel (Phyllanthus reticulatus), known locally as klan, and the bark of mountain or red-tipped ru (Cassuarina junghuhniana), known locally as ai gou. Phyllanthus reticulatus has been found to contain polyphenols and flavonoid glucosides (Lam, Wang, Chen and Lee 2007).

The mud-dyeing process seems to differ from dyer to dyer. Some take their yarns to the local pond and treat them there, first immersing their skeins in the mud and rinsing them. In the meantime they prepare a tannin-rich solution by boiling the leaves of klan in water mixed with more mud. The rinsed yarns are placed in a tub, soaked with the hot solution and then trampled and kneaded before being rinsed and hung on a bamboo frame to dry, a cycle that is repeated multiple times throughout the day. To complete the process, the yarns are kneaded in a solution prepared by boiling strips of ai gou bark with the ash from maize kernels, banana and lemon leaves and a sliver of beeswax before being finally rinsed and dried (Barrkman 2014, 197). Other dyers collect the mud and take it home, mixing it in a bath with indigo liquid and immersing the indigo-dyed yarns. The yarns are wrung out, covered in boiled klan extract, immersed in the thick mud and left to soak. After being wrung out again, the yarns are rinsed and the process repeated again until the required shade of black is achieved.

Plain and ikatted yarns dyed with indigo and mud by the Kemak people of Ilat Laun, Marobo, Bobonaro District, Timor-Leste (Images courtesy of Joanna Barrkman)

Return to Top

India

In Nagaland the Angami Nagas obtain their black by first dyeing their yarns blue by means of repeatedly boiling them with the leaves of tsopru, a wild indigo-like plant (vein leaf acanthus, Strobilanthes flaccidifolius), and drying them in between. They are then buried in mud for a couple of days before one final washing and rinsing. It is thought that the leaves of tsopru contain gallic acid (Ghosh and Ghosh 1995, 172). The same technique is used by some of the tribal groups in Manipur (Ghosh and Ghosh 1997, 151).

Return to Top

Burma

Mud-dyeing was used in various parts of Burma, such as Tharawaddy, to obtain a good black or dark brown, using various tannin-rich fruits and barks especially myrobalan (Fraser in Scott and Hardiman 1890, pt. 1, vol. 2, 383-384). Iron seems to have been most frequently obtained from iron filings. However an earlier report recorded that the fruit of myrobalan (Terminalia chebula) was mixed with iron clay to produce a very good black dye (Mason 1850, 181).

The Karen in Shan State once produced a light black by soaking their cotton overnight in a bath of mashed maisi leaves and then leaving it in the mud of a buffalo wallow for 24 to 36 hours (Leveson in Scott and Hardiman 1890, pt. 1, vol. 2, 398). According to Alexandra Green, some of the more remotely located Karen continue to use this technique today (Green 2008, 24).

Return to Top

Thailand

In the past it was traditional for many village dyers to fix natural colours such as blue, black and turmeric yellow by immersing their cotton fibres in smooth mud collected from buffalo wallows or from the riverbed (Conway 1992, 61, 69, 71 and 77). Local mud-dyed fabrics were valued for their softness and ease of wear. Today mud-dyeing only survives in a few locations.

In Isaan dyers produce a blackish grey by using the bark of the samor tree before immersing their threads in mud (Stone 2009, 166 and 168).

The village of Amphur Nong Buadang in Chaiyaphum Province, northeast Thailand, has a local tradition of dyeing with mud (Veerapreeyakul 2008, 151). This has recently been revived by a local women's cooperative where they combine the mud-dyeing process with the traditional narrow-striped ikat technique called mud mee. After binding their cotton yarns, they are dyed with various roots and barks and are then post-mordanted with mud.

Mud-dyeing was also traditional among the Phuthai in the traditional silk-weaving region of Mukdahan Province in the Mekong Valley. They used the same process for camouflaging their fishing nets (Smanchat 2014, 14). In 1996 the method was revived to dye pha sin skirts in Nong Sung village. Weavers initially dye their silk yarns with the dyewoods ken-kai (cockspur thorn, Maclura cochinchinensis), and pae-ka (the Indian trumpet tree, Oroxylum indicum), and then fix them using mud from ponds that are believed to be at least one hundred years old.

Pha mak khlon drying at Ban Na Ton Chan

In the khit-weaving village of Ban Na Ton Chan in northern Sukothai Province, local women have developed a novel mud-dyeing process. Indigo threads are woven into traditionally patterned pha mak khlon, which are then immersed overnight in a container of filtered pond mud. After washing, the cloths are then overdyed in a boiling bath of either lac, the fruit of the ebony tree, or some other dyewood.

Return to Top

Vietnam

In Vietnam dyers use the tannin-rich dyeing yam, Dioscorea cirrhosa, a climber that grows wild in forested or mountainous areas. It was once traded as a source of both tannins and a natural brown dye (Bechtold and Mussak 2009, 71-72). The tubers were harvested from plants that were over three years old and were rasped into water and boiled. After dyeing the fabric with the brown tannins, it was soaked in black mud to produce a fast black.

Return to Top

The Philippines

The Mandaya of eastern Mindanao produce an abaca ikat cloth called dagmay, which they sew into linaog tubeskirts. They dye their abaca yarns black using a combination of tannin-rich bark and iron-rich mud. They first pound the tree bark and then boil it with the abaca yarn. They then add a bluish-coloured mud collected from specially selected locations and allow the yarns to steep for one or more hours to achieve the desired tone (Hamilton 1998, 50).

A Mandaya dagmay (abaca) ikat cloth decorated with stylised human figures and crocodiles (Image courtesy of the Museum of Fine Arts, Boston)

The Muslim Maranao of northern Mindanao obtain black by submerging their presumably tannin-dyed yarns in mud for several days (Madale 1998, 156).

The Aeta of Polillo Island, close to Luzon Island, used mud to stain their barkcloth a deep brown and decorated it with geometric designs using citrus juice (Fox 1952, 257)

Return to Top

Japan

There is a very strong tradition of mud-dyeing on the sub-tropical island of Amami Ōshima, the largest of Japan’s Satsunan islands, which sit between the main island of Kyūshū and Okinawa in the northern part of the Ryūkyū Archipelago, southern Japan. Here mud-dyeing is called dorozome. Local dyers believe that the technique was discovered by accident. When Japanese samurai conquered the island in the early seventeenth century, they demanded the island’s kimonos as tribute. Some rebellious islanders hid their kimonos by burying them in the ground. When they were dug up they had turned a beautiful dark grey.

The basic process involves soaking the silk yarns or textiles in a tannin-rich dye bath made by boiling wood chips from the sharinbai (Yeddo Hawthorn) tree. Some 600kg of wood chips are boiled for 14-16 hours at a time. The chips are then used as firewood and the left over wood ash is used for indigo-dyeing. After dyeing the yarn or cloth it is rinsed and immersed in a pit of mud from a rice paddy. Various plants are added to the rice paddy to increase the iron content. This process is then repeated from 80 to 100 times to achieve the desired colour of black.

Yukihito Kanai, a master dyer from Amami Ōshima, demonstrates dyeing cotton in the sharinbai dye bath

Mordanting hanks of silk yarn in a mud pit on Amami Ōshima

On Amami Ōshima dorozome is mainly used to produce a unique type of silk ikat called tsumugi, renowned for its precise patterns. The most famous type is a complex double ikat know as tate-yoko gasuri, which involves 40 individual processes and can take 18 months to make a single roll of fabric for one kimono which can easily cost over $50,000. In tate-yoko gasuri, the silk yarns are woven and dyed to produce a temporary fabric, which is then unpicked. Each single thread is then hand coloured and rewoven, resulting in incredibly fine and precise patterns.

A section of silk tsumugi from Amami Ōshima

At its peak in around 1980 some 20,000 people worked in the Amami Ōshima tsumugi industry, but since then there has been a steep decline in demand and production.

Return to Top

The Biochemistry of Stagnant Ponds

The chemistry of mud-dyeing has never been properly analysed and is likely to be complex. Nevertheless it is possible to gain some insight into the processes involved.

We first need to understand how ferrous iron is produced in stagnant rivers and ponds. Iron is the fourth most abundant element in the Earth's crust and leaches into freshwater rivers, lakes and ponds from the soil and weathered rocks. However iron is extremely insoluble in water so its concentration in most natural freshwaters is very low, not exceeding 1mg per litre (Wang and Dou 1988). Iron is mainly present in the form of particulate matter – the ratio of dissolved iron to particulate iron is around 1:500 (Davidson and DeVitre 1992).

Both the concentration and the speciation (either ferrous or ferric) of iron in water depend on many factors such as water flow, the pH of the water, its chemical composition, incident light and the amount and type of dissolved organic matter (Vuori 1995). In so-called oxic waters (where oxygen is present) with neutral pH, ferrous iron Fe(II) is rapidly oxidised into much more stable ferric iron Fe(III), which precipitates as highly insoluble oxides and hydroxides (Xing and Liu 2011). This oxidation is very pH sensitive and accelerates with increasing pH (alkalinity).

In anoxic waters, devoid of oxygen, iron is mainly found in the ferrous state Fe(II), usually in the form of dissolved ions - although it will combine to form insoluble salts if there are high concentrations of carbonate, sulphide or orthophosphate ions. Under the right conditions there are various ways that ferric iron can be naturally reduced to ferrous iron, although the mechanisms are still poorly understood (Vuori 1995). It can be achieved by the action of bacteria, dissolved sulphides and certain organic compounds, by photo-reduction, or by the reaction of enzymes (Davidson and DeVitre 1992).

A stagnant wallow in the hills above Pau, where mud is collected for mud-dyeing

In oxic water aerobic bacteria survive by consuming oxygen, ultimately ‘reducing’ it to water and carbon dioxide. The solubility of oxygen in water at 20°C is only 9mg per litre and less at higher temperatures. In a warm stagnant tropical pond the rate of diffusion of oxygen from the atmosphere is slow relative to the speed of microbial metabolism. Consequently oxygen is quickly depleted, not only by the action of bacteria but also by the biological degradation of organic matter.

When oxygen is depleted, aerobic bacteria can no longer survive and anaerobic bacteria take over. Anaerobic bacteria obtain their energy from oxidants other than oxygen. In order of decreasing energy production these are nitrate, manganese, ferric iron, sulphate and, ultimately, carbohydrate and carbon dioxide. The aerobic bacteria are first replaced by nitrate-reducing bacteria, which convert nitrates into gaseous nitrogen. When the nitrates are exhausted, the nitrate-reducing bacteria are replaced by ferric oxide-reducing bacteria, which convert ferric iron into ferrous iron. The process continues until finally the methanogenic bacteria take over and convert carbonates into methane (Lovley and Klug 1983; Ward and Winfrey 1985).

This explains why mud from stagnant water sources contains ferrous iron. The reason that ferrous iron is so important is because it is far more reactive than ferric iron.

Return to Top

The Chemistry of Dyeing with Iron and Tannins

In our review of the chemistry of tannin dyes we showed how tannins are complex mixtures of polyphenols - organic chemicals containing multiple phenol units. There are two types:

- hydrolysable tannins, which predominate in the leaves and fruit of trees. They are esters of gallic acid and a polyhydric alcohol, which in most cases is D-glucose. They are divided into two groups – gallotannins and ellagitannins. They are relatively stable to air, but are easily hydrolysed back into sugars and their related polyphenolic acids - either gallotannins or ellagitannins

- condensed tannins, which are more likely to be found in the bark or wood of trees. They have no polyhydric alcohol core and are simply polymeric flavonoids, many just simple polymers of either catechin or epicatechin. They are unstable in air but are not easily hydrolysed.

We must emphasise once more that the chemistry of tannins is extremely complex.

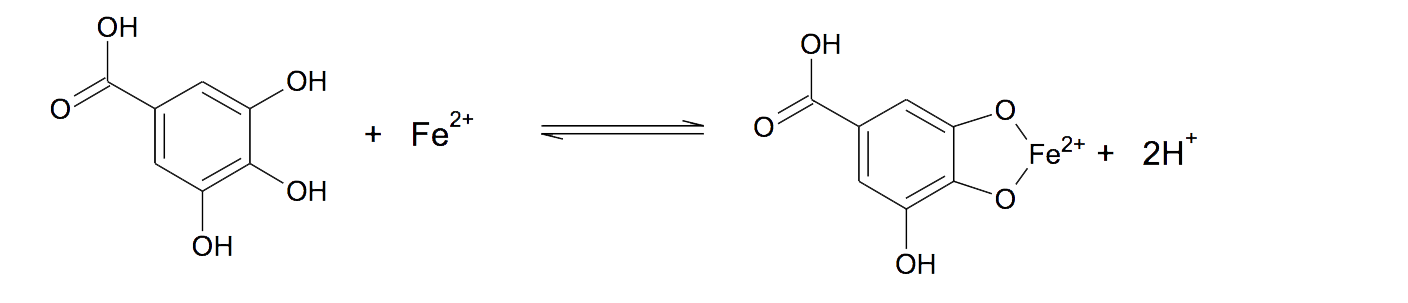

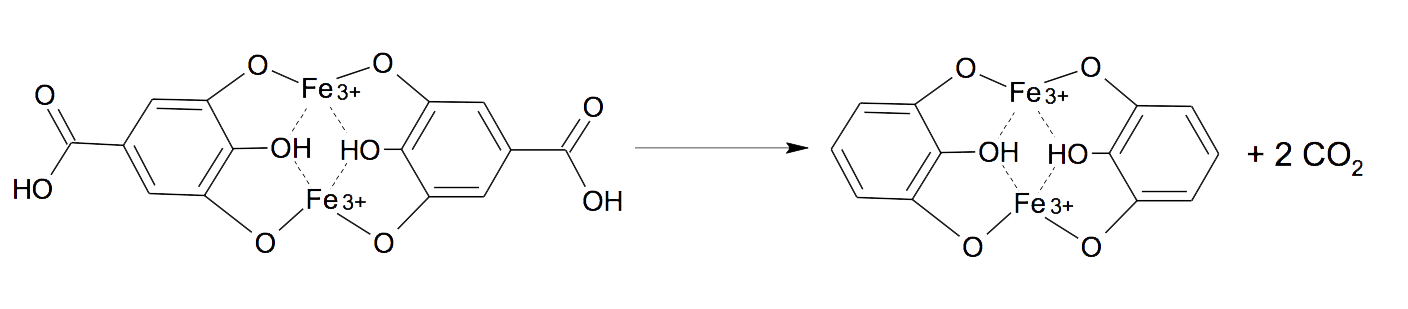

The process of dyeing with iron and tannins depends on the presence of ferrous iron. A convenient source of ferrous iron is stagnant mud, but it can also be obtained by adding metallic iron, in the form of iron filings for example, to a weak acid. Ferrous iron reacts with both hydrolysable tannins and condensed tannins, although in different ways. However, in each case, the ferrous iron complex auto-oxidises in the presence of air to form more stable ferric iron complexes.

Insights into the process involving hydrolysable tannins have arisen from research into the chemistry of iron gall inks. When hydrolysable tannins are boiled, especially in the presence of acid, they are hydrolysed into gallic acid. The ferrous iron then reacts with the gallic acid to form a ferrous complex, which then oxidises into the equivalent ferric tannate complex. The complex was first investigated in 1994 by Christian Wünderlich, who discovered that it contained equal proportions of ferric iron and gallic acid. Christoph Krekel analysed the complex more thoroughly in 1999 and concluded that it was actually ferric pyrogallol.

It is formed as follows. Firstly the ferrous iron reacts with gallic acid to form ferrous gallate and two protons, in other words it generates an acid (Jancovicová 2007, 392). For example if the iron is in the form of ferrous sulphate, the reaction will generate sulphuric acid. Pure ferrous gallate is white and is water soluble.

In the presence of oxygen, the ferrous gallate immediately oxidises into ferric gallate:

Free ferric ions then catalyse the removal of the carboxyl groups from the ferric gallate to produce ferric pyrogallate, also called ferric pyrogallol, a complex that is violet-black and insoluble in water.

One disadvantage of ferric pyrogallate dye is that it can be corrosive, and in time can destroy the silk or cotton textile substrate. There seem to be several reasons for this. The first is that tannins are intrinsically acidic, containing phenolic and carboxylic functional groups (Timar-Balazsy and Eastop 2012, 96). The second is the presence of small amounts of sulphuric acid, formed from sulphates in the ferrous mud. This is exacerbated if there is an imbalance in the concentrations of gallic acid and iron salts, the gallic acid not being concentrated enough (Cardon 1998, 76). The third is that the acid hydrolysis of cellulose can produce reducing agents that convert ferric ions into reactive ferrous ions, which then catalyse the oxidative degradation of cellulose (Botti, Mantovani and Ruggiero 2005). These are the reason that many historical iron-tannate dyed textiles have discoloured and become damaged, in the worst case just crumbling to dust. No effective stabilisation treatments are currently known.

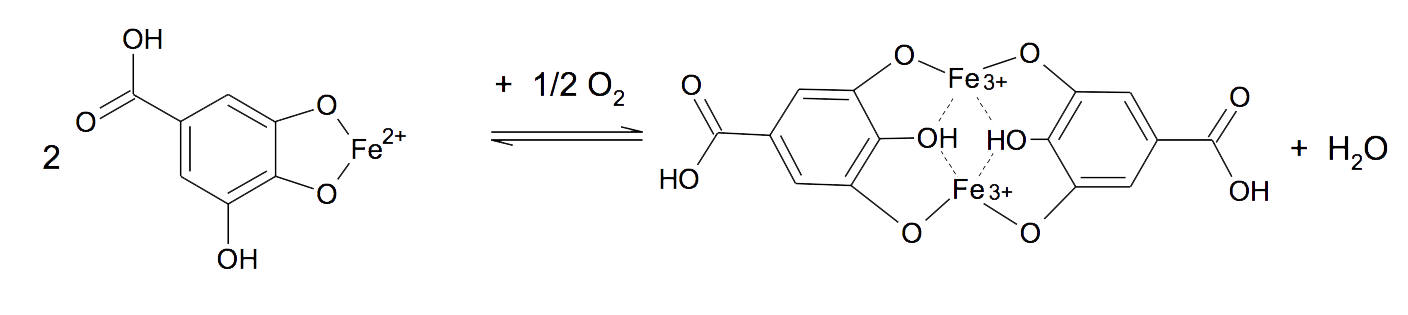

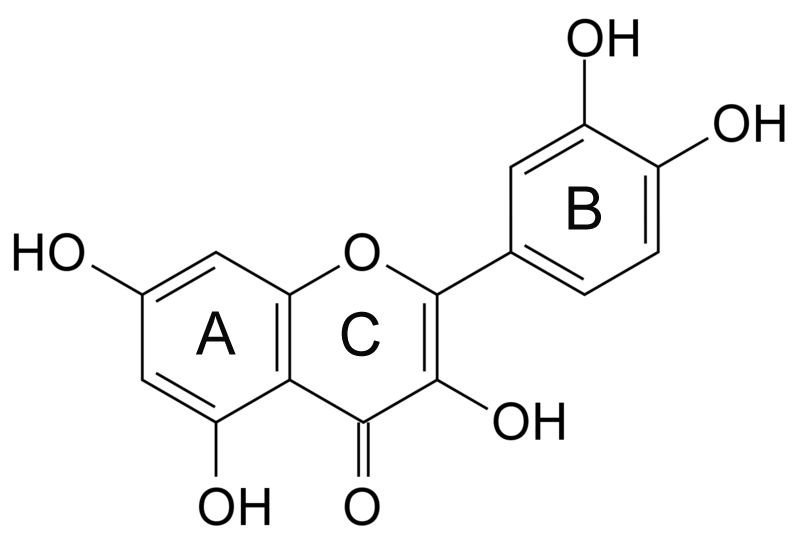

Turning to the process involved with the condensed tannins, it seems that the ortho-dihydroxyl group on the B-ring of the flavonoids that make up condensed tannins is responsible for forming complexes with metals (Slabbert 2012, 421).

The ortho-hydroxyl groups (ortho = adjacent) on the B-ring of a simple flavonoid

The ferrous iron reacts (chelates) with the ortho-phenols to produce complexes that are not highly coloured and are much less stable than their corresponding ferric iron equivalents (Slabbert 2012, 427). In the presence of air, the ferrous complexes oxidise into highly coloured ferric ortho-phenol complexes.

The nature of the complexes formed depends on the pH. With increasing pH (alkalinity) the ferric complexes become larger, transforming from mono-chelated to di- and tri-chelated complexes (Slabbert 2012, 421). The intense colouration of these complexes is due to charge transfer processes. Although similar complexes are formed with aluminium, these are colourless.

Although ferrous iron in the presence of oxygen oxidises slowly to ferric iron, the presence of phenolic acids, whether containing galloyl or catchol groups as in hydrolysable or condensed tannins respectively, greatly increases the rate of oxidation (Watson, Preedy and Zibadi 2013, 317).

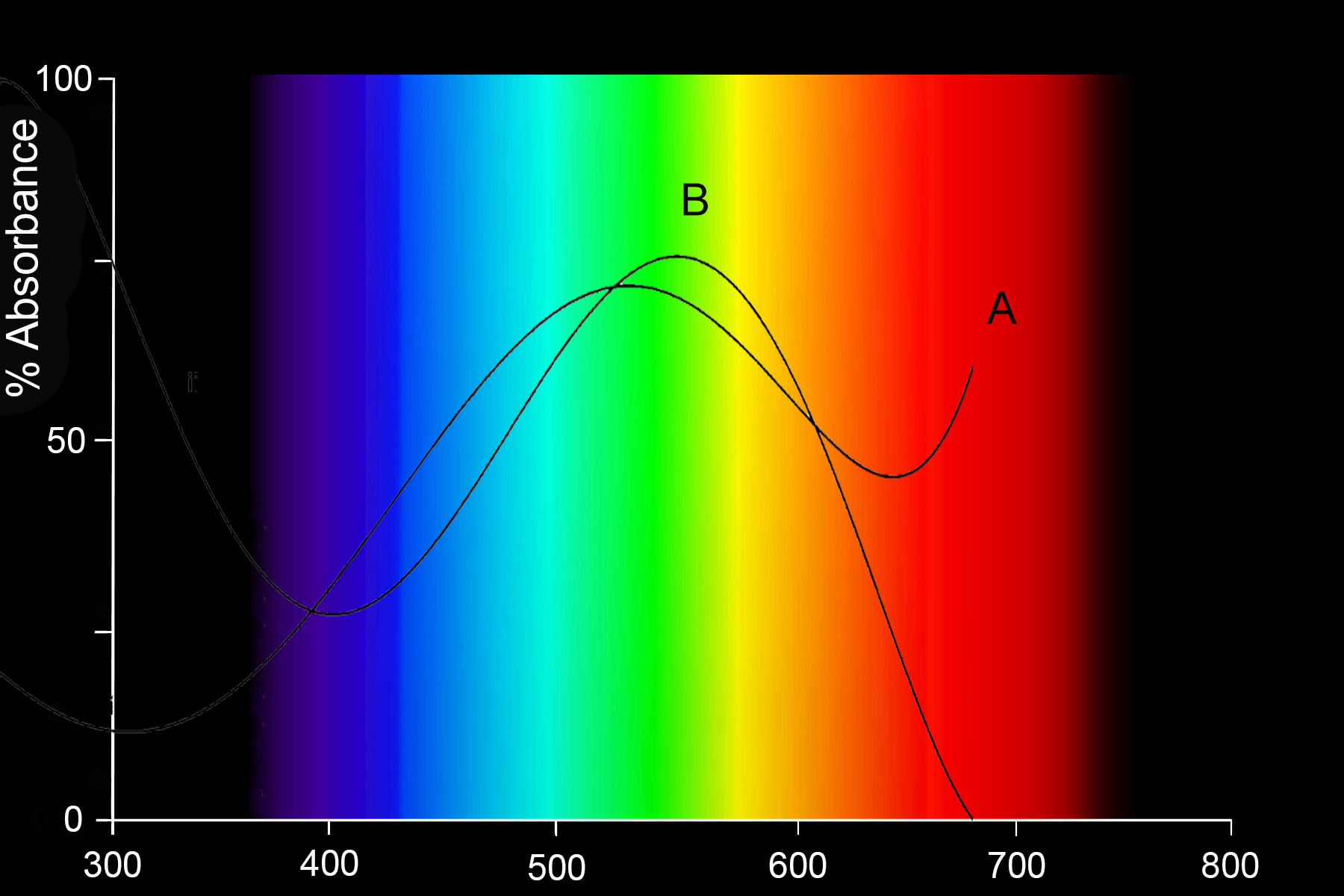

At pH 6.0 (just slightly acidic), ferric iron is typically bound to two catecholate groups or two or three gallate groups per metal ion (Peron, Wang, DeGuire, Jenkins, Lawson and Brumaghim 2010). Their wavelengths of maximum absorption, λmax, range from 542 to 561nm (green) for gallates and 561 to 586 (yellow) for catecholates, roughly in the centre of the visible light spectrum.

Absorbance curves for the binary ferric gallate complex A and the tertiary ferric gallate complex B. Neither is truly black (Fazary, Taha and Ju 2009)

One of the disadvantages of ferric tannate dyes is that they readily fade when exposed to light. One study found that a mud-dyed ceremonial skirt or lau from Sumba showed one of the highest levels of fading, out of a collection of 39 naturally and synthetically dyed textiles from Southeast Asia and India exposed to tungsten-halogen light for a cumulative 945 hours spread over a period of four months (Ford 1992). Only one textile showed greater light sensitivity - a turmeric dyed cotton shoulder cloth from India.

Return to Top

Bibliography

Adams, M. J., 1971. Work Patterns and Symbolic Structures in a Village Culture, East Sumba, Indonesia, Southeast Asia, vol. 1, pp. 321-334, Center for Vietnamese Studies, Southern Illinois University at Carbondale.

Böhmer, Harold, 2002. Koekboya: Natural Dyes and Textiles, REMHÖB-Verlag, Ganderkesee.

Burkill, Isaac Henry, 1966. A Dictionary of the Economic Products of the Malay Peninsula, vols. I and II, Governments of Malaysia and Singapore.

Cardon, Dominique, 2007. Natural Dyes: Sources, Tradition, Technology and Science, Archetype Publications, London.

Chairat, M., Bremner, J. B. and Chantrapromma, K., 2007. Dyeing Cotton and Silk yarn with the Extracted Dye from the Fruit Hulls of Mangosteen, Garcinia mangostana Linn, Fibres and Polymers, vol. 8, no. 6, pp. 613-619.

Clark, Matthew, 2011. Handbook of Textile and Industrial Dyeing: Principles, Processes and Types of Dyes, Cambridge.

Cunningham, Anthony B.; Maduarta, I. Made; Howe, Jean; Ingram, W.; and Jansen, Steven, 2011. 'Hanging by a Thread: Natural Metallic Mordant Processes in Traditional Indonesian Textiles', Economic Botany, vol. XX, issue X, pp. 1–19.

Doherty, William, 1891. The Butterflies of Sumba and Sumbawa, with some account of the island of Sumba, Journal of the Asiatic Society of Bengal, Vol. LX, part II, no. II, pp. 19-197, Calcutta.

Geirnaert-Martin, Danielle C., 1992. The Woven Lands of Laboya: Socio-cosmic ideas and values in west Sumba, eastern Indonesia, The Centre of Non-Western Studies, The Netherlands.

Geirnaert, Danielle C., 1993. The Sumbanese Textile Puzzle: A Comparitive Excercise, Weaving Patterns of Life: Indonesian Textile Symposium 1991, pp. 203- 228, Basel.

Gronovius, D. J. van den Dungen, 1855. Beschrijving van het eiland Soemba of Sandelhout, Tijdschrift voor Neerlands Indie, vol. 17, no. 1, pp. 277–312.

Hamilton, Roy W., 1994. 'Textile Technology', in Gift of the Cotton Maiden: textiles of Flores and the Solor Islands, Hamilton, Roy W., (ed.), pp. 58–77, Los Angeles.

Holmgren, Robert J., and Spertus, Anita E., 1989. Early Indonesian Textiles from Three Island Cultures: Sumba, Toraja, Lampung, Metropolitan Museum of Art, New York.

Hoskins 1993. The Play of Time: Kodi Perspectives on Calendars, History, and Exchange, University of California Press, Berkeley, Los Angeles, and London.

Janick, Jules; and Pauli, Robert E., 2008. The Encyclopedia of Fruit and Nuts, CABI.

Jansen, P. C. M., and Cardon, D., 2005. Dyes and Tannins, PROTA Foundation, Wageningen.

Jasper, J. E., and Pirngadie, Mas, 1912. De Inlandsche Kunstnijverheid in Nederlandsch Indië, Deel II, De Weefkunst, Mouton, The Hague.

Kajitani, Nobuko, 1980. 'Traditional Dyes in Indonesia', in Indonesian Textiles: Irene Emery Roundtable on Museum Textiles 1979 Proceedings, Textile Museum, Washington, D.C.

Keller, Edgar, 1993. Barkcloth Production and Dress in Laboya, West Sumba, Weaving Patterns of Life: Indonesian Textile Symposium 1991, ed. Nabholz-Kartaschoff, M.; Barnes, R., and Stuart-Fox, D., pp. 247–270, Basel.

Kruseman, J. D., 1836. Beschrijving van het Sandelhout Eiland, De Oosterling, 2, pp. 63–68.Lemmens, R.H.M.J., and Wulijarni-Soetjipto, N., 1991. Dye and Tannin Producing Plants, Prosea, Bogor.

Liles, J. N., 1990. The Art and Craft of Natural Dyeing: Traditional Recipes for Modern Use, University of Tennessee Press, Knoxville.

Nooy-Palm, Hetty, and Schefold, Reimar, 1986. Colour and anti-colour in the Death Ritual of the Toraja, Archipel, vol. 32, no. 1, pp. 39-49.

O'Neill, Charles, 1862. A Dictionary Of Dyeing And Calico Printing: Containing A Brief Account Of All The Substances And Processes In Use In The Arts Of Dyeing And Printing Textile Fabrics, London.

Roos, S., 1872. Bijdrage tot de Kennis van Taal, Land en Volk op het Eiland Soemba, Verhandelingen van het Bataviaasch Genootschap van Kunsten en Wetenschappen, vol. XXXVI, Batavia.

Subagiyo, Puji Yosep, 2007. Indonesian Natural Dyeing Recipes, Jakarta.

Tab, Nilanidhi, and Rabieb, Prachankadee, 1963. Active principles of Diospyros mollis, Proceedings of the Ninth Pacific Science Congress, vol. 5, pp. 52-54, Bangkok.

Ten Kate, Herman F. C., 1894. Verslag eener Reis in de Timorgroep en Polynesië, III Soemba, Tijdschrift van het Kon. Nederlandsch Aardrijkskundig Genootschap, Tweede Series, vol. XI, pp. 541-638, Leiden.

Vankar, Padma S.; Shanker, Rakhi; and Wijayapala, Samudrika, 2009. Dyeing Cotton, Silk and wool yarn with Extract of Garcinia Mangostana Pericarp, Journal of Textile and Apparel, Technology and Management, vol. 6, issue 1, pp. 1-10.

Zollinger, Heinrich, 2003. Color Chemistry: Syntheses, Properties, and Applications of Organic Dyes and Pigments, Zürich.

Publication

This webpage was first published on 4th November 2019.